3D Printing

Figure 1 : 3D-printing-2-300×232.jpe

General Information:

What is 3D printing?

3D printing could be described as a process used in making three dimensional (3D) objects from a 3D digital data file. The printer will build the required object by creating layers. Different types of materials including plastic, resin, and metal could be used in creating the final product. 3D printing will enable us to design and make complex (functional) shapes with less materials than traditional manufacturing methods. This technology will make the manufacturing quick and easy, and assist the engineers to work through design issues in hours rather than weeks.

It is treated as one of the most versatile disruptive technologies currently present. It also has the ability to create prototype examples before mass production, enabling lower costs.

The cost of a 3D Printer will be in the range of $1,000-$500,000, depending on the required final product and the materials used.

3D printing has made its way into many sectors including: hospitals, universities, automobile repair shops, research labs, space crafts and aviation companies, to name a few. With the aid of 3D technology, the aviation companies have been successful in manufacturing cheap, light-weight parts for their aircrafts, making the companies more profitable. Introducing light weight parts allow the aircrafts to become more fuel economical, enabling them to fly longer distances and encouraging cheaper airfares as well.

Please use the following link to view an interesting video clip on 3D printing.

Technical and Historical Information:

In the 1980s a new way of industrial fabrication called Additive fabrication was proposed. With this method 3D objects are produced by adding layers of materials and this process became popular as 3D printing. In the initial stages of 3D printing, the scientists used UV (Ultra Violet) light to harden liquid polymers in the process of creating the 3D object. Over the years, various types of additive technologies have been proposed, varying from Photopolymerization to Fusion Deposition and have progressed up to Bio-printing, in recent times. You will find plenty of open-source software available on the web to assist users in the fabrication process. As the prices of 3D printers are becoming affordable, we are also looking ahead for a huge growth in the 3D printing sector.

Prior to the introduction of additive fabrication, the traditional method of industrial fabrication was called Subtractive fabrication, which involved removing material from a solid block to achieve the required shape. Lathes and milling machines are a couple of examples.

There is another popular way of fabrication involving 3D objects which obtain the required shape by forming liquid or plastic material in the shape and allowing materials to solidify. This is widely used in Prototyping.

With the introduction of computers in the 2nd half of the 20th century and the development of design software such as CAD (Computer aided design) and CAM for manufacturing, the designing, fabrication and prototyping technology has been revolutionised in a big way. The 3D printing support in popular Microsoft Operating Systems 8.1 and onwards is also an important factor, as a form of encouragement given to the Microsoft users in exploring 3D printing options/capabilities. 3D Builder is a 3D printing software, which is available for free with the MS Windows 8.1 operating system.

There are many organisations who are into developing 3D Printing software and 3D printing devices. 3D Systems is an organisation, which is actively engaged in developing 3D Printing technology by interfacing with different types of sectors. 3D Systems’ D2P software will assist medical professionals in creating 3D modules such as Cardiovascular modules and sending them to the 3D printer to obtain the final product. By looking at the 3D model, physicians are able to navigate around delicate veins and arteries and learn the patient’s anatomy, which will assist in deciding on the appropriate treatments.

3D printing is becoming cheaper in creating single/multiple items and having a huge impact on manufacturing. If you look into the history – the impact on the introduction of the steam engine in 1750, printing press in 1450 and the transistor in 1950 – all of these also managed to create a huge impact on their related sectors.

Impact of Technology:

In the medical sector, 3D printers are used to replicate complex surgery procedures by assisting doctors to practice in a realistic environment.

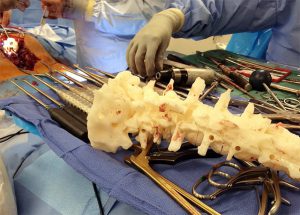

A personalized anatomical model printed on a 3D Systems SLA (stereolithography) ProX 800 3D printer was used for reference during Mark Weimer’s spinal operation.

Figure 2:Spinal-code-300×215.jpg

Referring to the above image, the 3D models of the patient were used to design the trajectory of each pedicle screw. The FIREFLY design printed pedicle screw guides for each vertebra that required operation. The surgical guides and bone models were printed using the 3D Systems ProX-800, 3D printer. This printer is equipped with SLA technology (stereolithography system) and is used in building parts with very smooth surfaces. The SLA technology will assist in lowering production costs, fast delivery speeds, large capacities, accuracy and easy to use features.

With the fast growth of 3D printing technology, we might see 3D printed human organs being used for organ transplants, reducing the need to wait for the organ donations by humans.

Figure 3: Scienceabc.com. 3d-printed-body-parts(2015)

There are negative impacts on society as well. 3D printing has been used to create a working gun and it will be very difficult to stop the production and circulation of illegal objects in society.

Pictures of 3D printed guns

Figure 4: 3D-Guns.jpg

Another social impact could be described as, “Less personal interaction”, due to mass personalisation. Let us take an example: the basic home utensils such as spoons, plastic cups, plates will be able to be produced at home if your home is equipped with a 3D printer. You are not required to go to a shop to purchase them. This means less interaction with people, fewer incidental chats. But the interaction is so vital in building strong communities and this important requirement will be influenced with the popularisation of 3D printing technology.

The mass personalisation will also have an impact on sales for some organisations as well.

The future of 3D printing looks very interesting. Technologies such as Bio printing will be a controversial issue. In the past, removal of an organ from a human is a relatively permanent issue. But with the assistance of tissue engineering processes and 3D printing technology, the researchers have been able to create organs and living tissues by depositing living cells in precise layers, similarly to printing any other object.

In conclusion, 3D printing technology has the ability to disrupt any technology which associates with it.

References: